Why Flexibility Matters: Choosing the Right Supplier for Wholesale Flexible Hoses

In industries ranging from construction to agriculture, flexible hoses play a crucial role in daily operations. When sourcing these hoses wholesale, the choice of supplier can make or break the success of your business. Flexibility in the hose itself is essential, but the flexibility of your supplier is just as important. A supplier who understands your unique needs and can adapt to changing demands is invaluable. In this blog, we’ll explore why flexibility matters when choosing a wholesale supplier for Flexible hose wholesale and how to find the right partner for your business.

The Importance of Flexibility in Wholesale Partnerships

Flexibility in a wholesale partnership means more than just the ability to provide a range of products. It involves:

- Adaptability to Changing Needs: As your business grows or shifts, a flexible supplier can adjust their offerings to meet new demands.

- Customized Solutions: A supplier who can tailor products and services to your specific needs adds significant value.

- Responsive Support: A flexible supplier is responsive and quick to address issues, ensuring minimal disruption to your operations.

How to Choose a Flexible Supplier for Wholesale Hoses

1. Assess the Range of Products Offered

The first step in choosing a flexible supplier is to assess the range of products they offer. A diverse product catalog indicates a supplier who can meet a variety of needs:

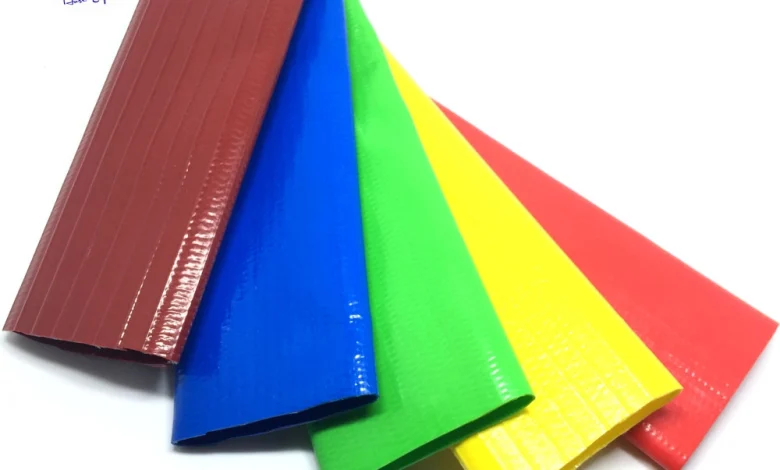

- Variety of Materials: Ensure the supplier offers hoses made from different materials, such as PVC, rubber, or polyurethane, to suit various applications.

- Size and Specification Options: Look for suppliers who provide hoses in multiple sizes, lengths, and pressure ratings.

- Specialty Products: Check if the supplier offers specialized hoses, such as food-grade, high-temperature, or chemical-resistant hoses.

Example: A food processing plant might require food-grade hoses with specific certifications, while a construction company might need heavy-duty hoses that can withstand high pressures and abrasive environments.

2. Evaluate Customization Capabilities

A truly flexible supplier will offer customization options. This allows you to get hoses that perfectly fit your application, improving efficiency and performance:

- Custom Lengths and Diameters: Ensure the supplier can cut hoses to the exact lengths you need, or produce hoses in non-standard diameters.

- Material and Design Customization: Look for suppliers who can modify materials, reinforcements, or other design aspects to meet your specific requirements.

- Private Labeling: If branding is important, consider suppliers who offer private labeling or customized packaging.

Example: An automotive manufacturer might need hoses with specific reinforcements to withstand the stresses of high-performance engines, and a flexible supplier can tailor the hose design accordingly.

3. Consider the Supplier’s Ability to Scale

As your business grows, your demand for flexible hoses will likely increase. A supplier’s ability to scale their production to meet your growing needs is critical:

- Production Capacity: Ensure the supplier has the production capacity to handle large or increasing orders without compromising quality or lead times.

- Inventory Management: Choose a supplier with robust inventory management systems to ensure they can scale up quickly when demand spikes.

- Supply Chain Resilience: Evaluate the supplier’s supply chain resilience—how well they can adapt to disruptions or changes in the market.

Example: A company involved in seasonal industries, such as agriculture or construction, will need a supplier who can ramp up production during peak seasons and scale back during off-peak times.

4. Assess the Supplier’s Delivery Flexibility

Delivery flexibility is another key factor. A supplier who can accommodate your delivery schedule and respond quickly to urgent needs is invaluable:

- Multiple Shipping Options: Look for suppliers who offer a range of shipping options, including expedited or same-day delivery for urgent needs.

- Flexible Delivery Schedules: Ensure the supplier can adjust delivery schedules based on your operational needs, such as delivering smaller quantities more frequently.

- Global Reach: If your operations are spread across multiple regions, choose a supplier with a global distribution network.

Example: A manufacturing facility might require just-in-time delivery to minimize inventory costs, and a flexible supplier who can meet these delivery requirements would be a crucial partner.

5. Evaluate the Supplier’s Customer Service and Support

A supplier’s flexibility should extend to their customer service and support. Responsive and knowledgeable support can make a significant difference, especially in urgent situations:

- Technical Support: Ensure the supplier offers strong technical support, with experts who can help you choose the right hoses and troubleshoot any issues.

- Responsive Communication: Look for suppliers who are quick to respond to inquiries, whether it’s for a new order or an issue with a delivery.

- Problem Resolution: Evaluate how the supplier handles problems, such as incorrect orders or product defects. A flexible supplier will be quick to rectify any issues.

Example: If a critical hose fails during operation, a supplier with responsive customer service who can provide immediate support and a replacement hose is essential to minimize downtime.

6. Check for Innovation and Adaptability

The best suppliers are those who not only meet your current needs but are also prepared to help you adapt to future challenges and innovations:

- Product Innovation: Choose suppliers who invest in R&D and regularly introduce new products or improved versions of existing products.

- Adaptation to Market Trends: Ensure the supplier stays up-to-date with industry trends and can quickly adapt their offerings to meet new market demands.

- Sustainability Practices: Consider suppliers who are innovating in sustainability, offering eco-friendly hoses or production methods that align with your corporate values.

Example: A supplier who develops new, more durable hose materials could help reduce replacement frequency and downtime in a mining operation, leading to long-term savings.

Conclusion

Choosing a flexible supplier for wholesale hoses is crucial to the success of your business. A supplier who can adapt to your changing needs, offer customized solutions, and provide responsive support will not only help you maintain efficient operations but also give you a competitive edge.

By assessing factors such as product range, customization capabilities, scalability, delivery flexibility, customer service, and innovation, you can find a supplier who is not just a vendor but a true partner in your business’s growth and success. Flexibility in both product and service will ensure that your operations run smoothly, regardless of the challenges that may arise.