A Comprehensive Guide to HOWO Under Chassis Parts

Introduction

In the world of heavy-duty trucking, few names resonate with reliability and performance as strongly as HOWO. Manufactured by the China National Heavy Duty Truck Group (CNHTC), HOWO trucks have earned their reputation for durability, particularly in demanding industries such as construction, mining, and logistics. Central to the performance and safety of these vehicles are the under chassis parts, which play a crucial role in load-bearing, stability, and overall functionality. This article aims to provide an in-depth examination of HOWO under chassis parts, exploring their structure, significance, common issues, maintenance strategies, and recent innovations in the field.

Section 1: Understanding HOWO Under Chassis Parts

1.1 The Importance of Under Chassis Parts

Under chassis parts form the backbone of any truck, especially for heavy-duty vehicles like HOWO. They contribute significantly to the overall performance and safety of the vehicle. Key reasons why these components are vital include:

Load Management: The under chassis parts, including the axles and suspension, are designed to manage and distribute the weight of the cargo effectively. This ensures that the truck remains stable even under heavy loads.

Safety and Control: The braking system and suspension components are essential for maintaining control over the vehicle, particularly during challenging driving conditions.

Ride Comfort: Well-designed suspension systems enhance ride comfort for both the driver and passengers, minimizing the impact of road irregularities.

Fuel Efficiency: Properly functioning under chassis parts contribute to better fuel efficiency by reducing rolling resistance and improving aerodynamics.

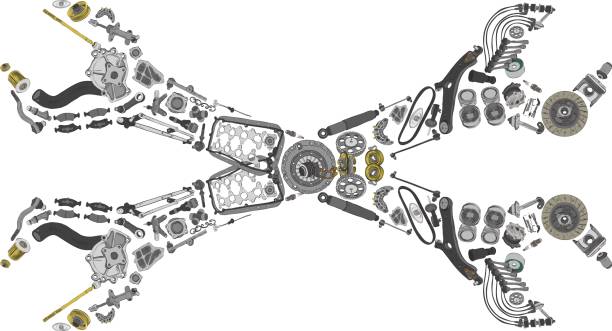

1.2 Components of HOWO Under Chassis Parts

The under chassis of a HOWO truck comprises several crucial components, each serving specific functions:

Frame: The frame is the structural foundation that supports all other components. Made from high-strength steel, it provides durability and stability.

Suspension System: This includes leaf springs, shock absorbers, and air suspension systems, which work together to absorb shocks from the road and maintain vehicle stability.

Axles: HOWO trucks typically feature front and rear axles that are essential for load distribution and power transmission.

Braking System: The air brake system, including brake drums and pads, is vital for ensuring effective stopping power, especially when carrying heavy loads.

Driveshaft: The driveshaft transmits power from the engine to the rear axle, making it an essential component for vehicle operation.

Section 2: Detailed Examination of Key Components

2.1 Frame

The frame of a HOWO truck is a critical component that determines the vehicle’s load-bearing capacity and structural integrity. Key aspects include:

Material: Typically constructed from high-strength steel, the frame is designed to withstand significant stresses from heavy loads and road conditions.

Design: The design of the frame affects the overall handling and stability of the truck. A well-engineered frame allows for better weight distribution and improved aerodynamics.

Corrosion Resistance: Rust and corrosion can weaken the frame over time. Manufacturers often apply protective coatings to enhance durability.

2.2 Suspension System

The suspension system is responsible for ensuring a smooth ride and maintaining vehicle stability. Its components include:

Leaf Springs: These are essential for load-bearing and provide flexibility to accommodate different weights. Over time, leaf springs can wear out, leading to reduced ride quality.

Shock Absorbers: These components dampen vibrations and prevent excessive bouncing. Worn shock absorbers can lead to poor handling and safety issues.

Air Suspension: Some HOWO models are equipped with air suspension systems that adjust based on the load. This technology offers improved ride quality and handling.

2.3 Axles

The axles in HOWO trucks are designed to handle heavy loads while providing stability. Key features include:

Differential: The differential allows the wheels to rotate at different speeds during turns, improving maneuverability. Regular maintenance of the differential is crucial for optimal performance.

Load Rating: HOWO axles are designed with specific load ratings to ensure they can handle the demands of heavy-duty operations. Exceeding these limits can lead to axle failure.

2.4 Braking System

The braking system is one of the most critical components for safety. Key elements include:

Air Brake System: HOWO trucks utilize an air brake system that offers superior stopping power. This system consists of an air compressor, brake chambers, and pneumatic lines.

Brake Pads and Drums: Regular inspection and maintenance of brake pads and drums are essential for ensuring effective braking performance. Worn components can lead to longer stopping distances.

Anti-lock Braking System (ABS): Many modern HOWO trucks come equipped with ABS technology, which prevents wheel lockup during braking, enhancing safety.

2.5 Driveshaft

The driveshaft is crucial for transmitting power from the engine to the axles. Key considerations include:

Alignment: Proper alignment of the driveshaft is essential to prevent vibrations and excessive wear. Misalignment can lead to drivability issues and damage to other components.

Universal Joints: These joints connect the driveshaft to the transmission and axles. Regular inspection and lubrication are necessary to prevent premature failure.

Section 3: Common Issues with HOWO Under Chassis Parts

Despite their robust design, HOWO under chassis parts can encounter several issues over time. Recognizing these problems early can help prevent costly repairs and ensure safe operation.

3.1 Suspension Problems

Worn Leaf Springs: Over time, leaf springs can sag or break, leading to a drop in load capacity and ride quality.

Shock Absorber Failure: If shock absorbers leak or lose their damping ability, the vehicle may experience excessive bouncing, leading to poor handling.

3.2 Axle Issues

Misalignment: Axle misalignment can occur due to impacts or wear, leading to uneven tire wear and compromised handling. Regular alignment checks are essential.

Differential Wear: The differential can wear out, affecting power distribution and traction. Regular lubrication and inspection can help mitigate this issue.

3.3 Brake System Failures

Worn Brake Pads: Neglecting to replace worn brake pads can lead to decreased braking efficiency and longer stopping distances, posing a significant safety risk.

Air Leaks: Any leaks in the air brake system can lead to reduced braking power, compromising safety during operation.

3.4 Driveshaft Problems

Vibrations: Misalignment or damage to the driveshaft can cause vibrations that may lead to further damage to the transmission or axle.

Universal Joint Wear: The universal joints can wear out, causing excessive play and noise, affecting performance.

3.5 Frame Damage

Rust and Corrosion: Frames are susceptible to rust, especially in humid environments. Corrosion can weaken the frame and compromise safety.

Deformation: Excessive loads or impacts can cause the frame to bend, affecting alignment and stability.

Section 4: Maintenance Strategies for HOWO Under Chassis Parts

To ensure the longevity and performance of HOWO under chassis parts, proper maintenance is essential. Here are some effective strategies:

4.1 Regular Inspections

Conducting regular inspections of under chassis parts is crucial. Key areas to check include:

Suspension System: Inspect leaf springs for cracks and sagging, and check shock absorbers for leaks.

Braking System: Regularly check brake pads and drums for wear and inspect air lines for leaks.

Axles and Driveshaft: Examine axles for signs of damage and ensure driveshaft alignment is maintained.

4.2 Lubrication

Proper lubrication of moving parts is vital for minimizing friction and wear. This includes:

Greasing Suspension Components: Regularly grease control arms and bushings to reduce friction and wear.

Driveshaft Maintenance: Ensure universal joints are well-lubricated to prevent premature wear and tear.

4.3 Timely Replacements

Components that show signs of excessive wear should be replaced promptly to avoid further damage. For instance:

Brake Pads: Replace worn brake pads to maintain optimal braking performance.

Shock Absorbers: If they show signs of leakage or failure, replace them immediately to avoid compromising ride quality and safety.

4.4 Rust Prevention

To prevent rust and corrosion, consider the following strategies:

Protective Coatings: Apply anti-corrosive treatments to the frame and other susceptible parts.

Regular Washing: Regularly wash the undercarriage to remove dirt, salt, and chemicals that can accelerate rusting.

4.5 Professional Servicing

For complex issues or if you’re unsure about the condition of your under chassis parts, seek professional help. Regular servicing by qualified mechanics ensures that any potential problems are addressed early, preventing costly repairs later.

Section 5: Innovations in HOWO Under Chassis Parts

Recent advancements in technology and materials have led to significant improvements in HOWO under chassis parts. These innovations focus on enhancing durability, safety, and efficiency.

5.1 Advanced Material Technologies

High-Strength Steel Alloys: New alloy formulations provide greater strength while reducing weight, contributing to improved fuel efficiency and load capacity.

Composite Materials: The use of composites in non-load-bearing areas helps reduce overall weight without sacrificing structural integrity.

5.2 Enhanced Braking Systems

Electronic Braking Systems (EBS): EBS technology provides improved response times and better control during braking, especially under heavy loads.

Regenerative Braking: Some newer models feature regenerative braking systems that recover energy during braking, improving overall efficiency.

5.3 Intelligent Suspension Systems

Adaptive Suspension: Advanced systems can adjust the suspension settings based on load and terrain, enhancing ride comfort and handling.

Self-Leveling Systems: These automatically adjust to load changes, maintaining optimal height and balance, improving stability during operation.

5.4 Diagnostic Technologies

Telematics Systems: Modern HOWO trucks often come equipped with telematics that monitor the performance of under chassis parts in real-time, providing alerts for maintenance needs.

Diagnostic Tools: Advanced diagnostic tools allow mechanics to quickly assess the condition of under chassis parts, making maintenance more efficient.

Section 6: Conclusion

In conclusion, HOWO under chassis parts are critical for the performance, safety, and longevity of these heavy-duty trucks. Understanding their components, functions, and common issues is essential for effective maintenance. By implementing regular inspections, timely replacements, and adopting modern maintenance strategies, truck operators can maximize the lifespan of their HOWO under chassis parts.

The ongoing advancements in materials and technology continue to enhance the durability and efficiency of these components, ensuring that HOWO trucks remain reliable in various demanding applications. With proper care and attention, HOWO trucks can deliver exceptional performance, safety, and value throughout their operational life.

This article is designed to provide a comprehensive understanding of HOWO under chassis parts while ensuring originality and depth. If you have any specific areas you would like to explore further or need additional information, feel free to ask!