Mastering Heavy-Duty Recovery: Why Hydraulic Winches Are the Ultimate Tool

When it comes to heavy-duty recovery operations, whether on construction sites, during off-road adventures, or in maritime applications, the right tool can make all the difference. For tasks that require moving massive loads, lifting heavy equipment, or recovering large vehicles, hydraulic winches have become the go-to solution due to their unmatched power and performance. If you’ve ever wondered why hydraulic winches are considered the ultimate tool for tough jobs, you’ve come to the right place.

In this blog, we’ll explore why hydraulic winches are the preferred choice for handling the toughest recovery operations. We’ll examine their core features, highlight their key benefits, and explore how they’ve revolutionized industries by offering efficient, reliable, and powerful performance in challenging conditions.

What Is a Hydraulic Winch?

Before we dive into the reasons hydraulic winch are the ultimate tool for heavy-duty recovery, let’s first understand what they are and how they work.

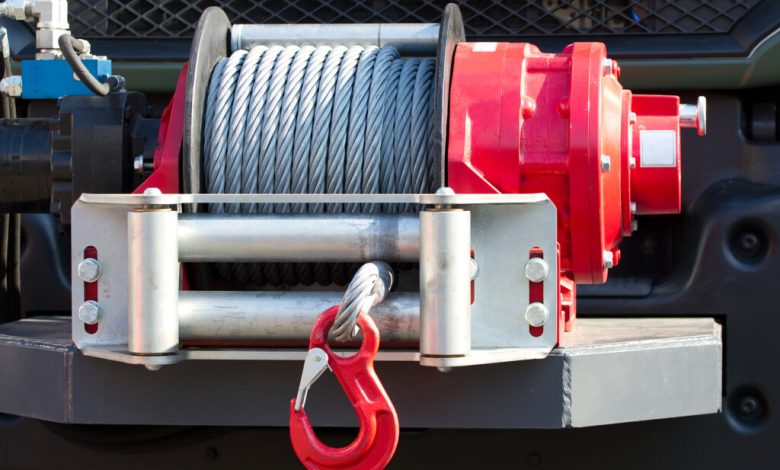

A hydraulic winch uses hydraulic power to operate a winch drum or spool. Unlike electric winches that rely on electricity or manual winches that require physical effort, hydraulic winches are powered by hydraulic fluid pressure, which is typically provided by the engine of a vehicle or a separate hydraulic power unit. The hydraulic fluid powers the winch motor, allowing it to lift, pull, or recover massive loads with ease.

Hydraulic winches are commonly used in demanding industries like construction, mining, offshore, and recovery operations due to their ability to handle high loads, perform in harsh environments, and operate continuously without power interruptions.

Why Hydraulic Winches Are the Ultimate Tool for Heavy-Duty Recovery

1. Unmatched Power for Heavy Loads

Hydraulic winches are designed to provide extraordinary pulling and lifting power, making them ideal for heavy-duty recovery operations. One of the most significant advantages of hydraulic winches is their ability to pull or lift massive loads that would otherwise be impossible for electric or manual winches to handle.

The hydraulic system provides a continuous and consistent flow of power, which translates to high torque and the ability to recover even the heaviest of vehicles or materials. Whether you’re trying to lift a large piece of construction machinery or recover a truck stuck in mud or sand, hydraulic winches deliver the force needed to get the job done efficiently and safely.

For example, on construction sites, hydraulic winch are often used to move large machinery, steel beams, or concrete slabs. In the case of off-road recovery, these winches can easily handle vehicles stuck in difficult terrain. Their powerful performance makes them essential tools for anyone working in environments where heavy lifting and recovery are the norm.

2. Continuous Operation Without Power Depletion

One of the key benefits of hydraulic winches is that they can operate continuously without the need to worry about draining a battery or running out of electrical power. This is a significant advantage over electric winches, which can lose power over time, especially when used for extended periods.

Since hydraulic winches are powered by the hydraulic system of a vehicle or a separate power unit, they can keep working as long as the hydraulic fluid supply is available. This feature is particularly important in industries and recovery operations where long-duration jobs are common, and there is no room for power shortages or delays.

For example, in off-road recovery, when a vehicle is stuck in difficult conditions like mud or snow, a hydraulic winch can provide the continuous power necessary to extract the vehicle without running out of energy or slowing down. In construction or mining, hydraulic winches can operate throughout the day, helping to move or lift materials without interruption.

3. Durability and Reliability in Harsh Environments

Another reason hydraulic winches are the ultimate tool for heavy-duty recovery is their durability and reliability, especially in harsh environments. These winches are built to withstand the toughest conditions, including extreme temperatures, wet environments, dust, and mud.

Hydraulic winches are designed to perform in challenging settings, making them perfect for construction sites, off-road recovery, marine applications, and even offshore oil rigs. In comparison to electric winches, which can be sensitive to wet or corrosive environments, hydraulic winches are far more resilient and capable of continuing operation in adverse weather conditions.

For instance, in marine applications, hydraulic winches are often used to pull boats out of the water, dock ships, or recover marine equipment. Since these winches are sealed and designed to operate in wet, salty environments, they can perform reliably even when exposed to harsh maritime conditions.

In mining or oil and gas fields, hydraulic winches are used to pull heavy loads of materials or equipment. These environments can be dusty, muddy, and prone to extreme weather, but hydraulic winches maintain their efficiency without losing power or performance.

4. High Precision and Control

In heavy-duty recovery operations, precision is key. Whether you’re recovering a vehicle from a precarious position, lifting heavy equipment, or pulling a load from a difficult spot, the ability to control the winch with accuracy is essential for safety and efficiency. Hydraulic winches excel in this regard by offering excellent control and smooth operation.

Hydraulic systems allow operators to adjust the speed of the winch and apply just the right amount of force, ensuring that loads are moved gradually and safely. This level of precision is vital in high-risk recovery situations, where there is a danger of damaging the load, the winch, or the surrounding environment.

For example, in off-road recovery, a hydraulic winch enables the operator to recover a stuck vehicle with minimal jerking or sudden movements, preventing additional damage to the vehicle. In construction or mining, hydraulic winches allow operators to lift and place heavy materials with pinpoint accuracy.

5. Minimal Maintenance and Longevity

Hydraulic winches require relatively low maintenance compared to electric winches, which often involve more complex electrical systems and batteries. The hydraulic components are built to last, and with proper care, hydraulic winches can operate for many years with minimal downtime.

Regular maintenance typically involves checking the hydraulic fluid levels, inspecting the hydraulic hoses and seals, and ensuring the system is free from contaminants. The system’s robust design and fewer moving parts mean that hydraulic winches are less prone to wear and tear, making them a more durable and cost-effective choice in the long run.

For industries that rely on recovery and lifting operations, this low-maintenance aspect is essential. With hydraulic winches, operators can spend less time on maintenance and more time getting the job done.

6. Versatility Across Industries

Hydraulic winches are incredibly versatile and can be used in a wide range of industries and applications. Here are some examples of where hydraulic winches are commonly used:

-

Construction Sites: Hydraulic winches are frequently used to move heavy machinery, materials, and equipment on construction sites. They help lift and position large beams, concrete slabs, and other bulky materials that are essential for building projects.

-

Off-Road Recovery: For off-road enthusiasts, hydraulic winches are essential for recovering stuck vehicles from mud, sand, or snow. The power and reliability of hydraulic winches make them the top choice for vehicles that need to be recovered in challenging terrain.

-

Marine and Offshore Operations: Hydraulic winches are widely used in marine applications for tasks such as pulling boats out of the water, docking ships, and recovering underwater equipment. Their ability to work in wet, corrosive environments makes them indispensable in the maritime industry.

-

Mining and Oil & Gas: Hydraulic winches are used in mining and oil & gas operations to transport heavy loads, pull large equipment, and support complex lifting tasks. These industries rely on the winches’ high power and reliability to keep operations running smoothly.

-

Search and Rescue: In emergency recovery situations, hydraulic winches play a vital role in rescuing vehicles, lifting debris, or pulling trapped victims from dangerous situations. The winches’ ability to provide continuous, precise power makes them invaluable tools for first responders.

Conclusion: The Ultimate Tool for Heavy-Duty Recovery

When it comes to heavy-duty recovery, lifting, and towing operations, hydraulic winches are the ultimate tool. Their unmatched power, continuous operation, durability in harsh conditions, and precision control make them an essential piece of equipment in industries where reliability is crucial.

Whether you’re on a construction site, off-roading, recovering a boat, or working in the mining industry, hydraulic winches deliver the performance needed to get the job done safely and efficiently. With their long lifespan, low maintenance requirements, and ability to operate in extreme environments, hydraulic winches are designed to tackle the toughest jobs with ease.

For anyone involved in heavy-duty recovery and lifting tasks, investing in a hydraulic winch is a game-changing decision that will ensure smooth, reliable, and powerful performance every time.